Recyclables which are collected separately comes directly to MRF plants. The waste those arriving to the facility shall be dumped a reception area in MRF building.

The main concept of our standart MRF plant, is primary screening by a screen and manuel sorting by hand pickers.

Waste material is feeded to bag opener bunker ,under the bunker there is an impact-resistant, steel plate and inclined feeding conveyor, designed for operation in hard conditions.

The rotation speed of machines in MRF including this conveyor, can be adjusted by means of frequency controller and as a whole it determines the total productivity of the sorting line.

From this dosing belt the material goes into drum sieve (trommel screen) , which initial part is equipped with cutting blades, designed to cut/open the nylon waste bags as much as possible.

In the drum sieve the fine fraction is separated. This fraction contains mostly organic materials and is not a subject to effective sorting. This fine fraction should be sent to pilot compost plant or landfilling

Because the fine organic fraction is separated by the drum sieve, the coarse fraction with greater than 80 mm is less polluted with organic inclusions and allows sorting. The fraction of greater then 80mm is discharged from the sieve via the sorting conveyor belt

The sorting conveyor leads to the sorting platform, where the valuable products are separated, such as glass, metals, plastic, paper and cardboard by hand pickers. A Magnetic permanent separator, located longitudinally over the sorting band with removes ferrous-magnetic (especially boxes) from the waste mass.

Sorted material is thrown from chute on platform to the containers. These containers are located under the sorting platform.

After the sorting , the residual material is discharged into hook- lift container by sorting conveyor which particular part is closed in outside the building. Unevaluated waste in this container is sent to landfill site.

Horizontal hydraulic baling press hreduces the volume and transforms materials into standard bales.

For baling the PET bottles, a perforator located on top of the press is preparing the PET bottles for baling.

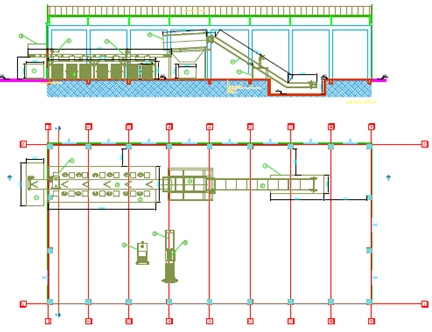

In the picture below , a simple MRF plant layout can be seen ;